Powder Coating Booths For Sale are essential for businesses and workshops aiming to achieve durable, high-quality finishes on metal, wood, or composite surfaces. These booths provide a controlled environment to minimize overspray, enhance coating efficiency, and ensure operator safety. Available in industrial-grade or compact models, they cater to automotive repair shops, aerospace manufacturers, furniture producers, and DIY enthusiasts. Modern units feature advanced airflow systems, fire-resistant materials, and powder recovery mechanisms, aligning with eco-friendly practices by reducing waste. Prices range from 5,000forbasicsetupsto100,000+ for automated systems. This guide explores key factors to consider when purchasing a Powder Coating Booths For Sale.

1. Powder Coating Booth For Sale Overview and Components

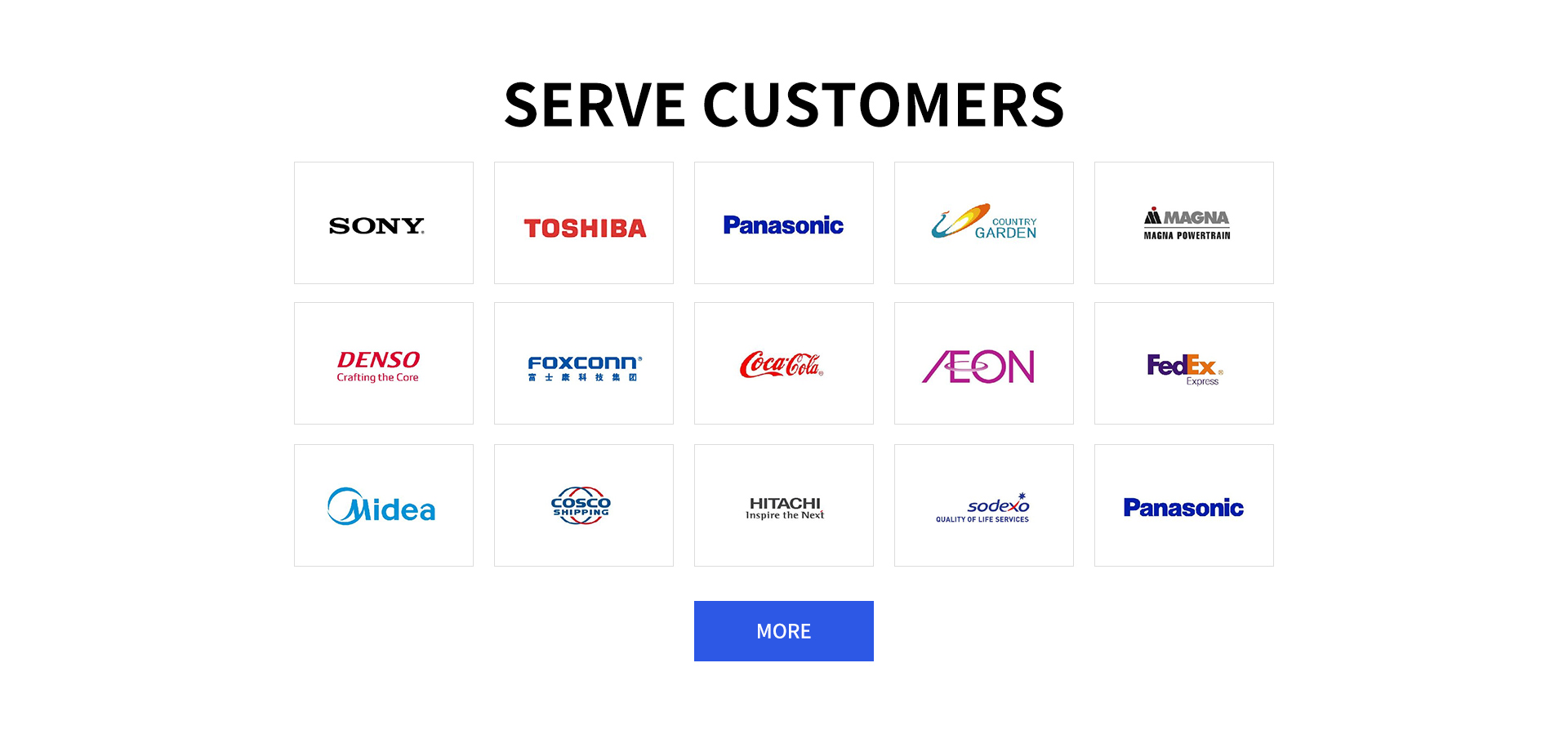

A Powder Coating Booths For Sale typically includes an enclosed workspace, ventilation system, and filtration units. Industrial models use galvanized steel or aluminum frames for durability, while smaller booths may feature modular panels. Core components include exhaust fans to maintain airflow, pre-filters for large particle capture, and cartridge filters or cyclones for powder recovery. Electrostatic spray guns, grounding systems, and lighting are standard. High-end systems integrate automated conveyors or touchscreen controls for precision.

2. Applications of Powder Coating Booths For Sale

Powder Coating Booths For Sale serve industries like automotive (coating wheels, engine parts), aerospace (corrosion-resistant finishes), and furniture (metal or wood coatings). Manufacturers of appliances, agricultural machinery, and bicycles rely on these booths for scratch-resistant surfaces. Small businesses use compact booths for custom projects, such as motorcycle parts or architectural fixtures. They are also ideal for repair shops refurbishing industrial equipment.

3. Design Considerations for Powder Coating Booths For Sale

When purchasing a Powder Coating Booths For Sale, prioritize safety and compliance. Ensure the booth meets OSHA and NFPA standards for fire resistance and ventilation. Opt for non-combustible wall materials like steel. Calculate airflow capacity (CFM) based on booth size to prevent powder buildup. Include explosion-proof lighting and emergency shutoffs. For energy efficiency, select variable-speed fans and insulated panels. Modular designs allow future expansion.

4. How to Choose the Right Powder Coating Booth For Sale

Evaluate your production volume, budget, and space. For small workshops, benchtop booths (5,000–15,000) suffice. High-volume facilities require industrial booths (30,000–100,000+) with automated recovery systems. Check compatibility with your powder type (e.g., thermoset or thermoplastic). Prioritize vendors offering warranties, installation support, and spare parts. Read reviews to assess reliability and after-sales service.

5. Q&A on Powder Coating Booths For Sale

Q: What is the average price of a powder coating booth for sale?

A: Prices start at 5,000forcompactmodels,whileindustrialsystemsexceed50,000.

Q: Can I buy a used powder coating booth for sale?

A: Yes, refurbished booths cost 30–50% less but verify their condition and compliance.

Q: How do I maintain airflow efficiency?

A: Clean filters weekly and replace them every 300–500 hours of operation.

Q: Are portable powder coating booths effective?

A: Portable units work for small projects but lack capacity for large-scale production.

Q: What safety certifications should I check?

A: Ensure compliance with NFPA 33, OSHA 1910.107, and EPA regulations.

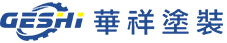

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com